Introduction: Laser Printing on Leather

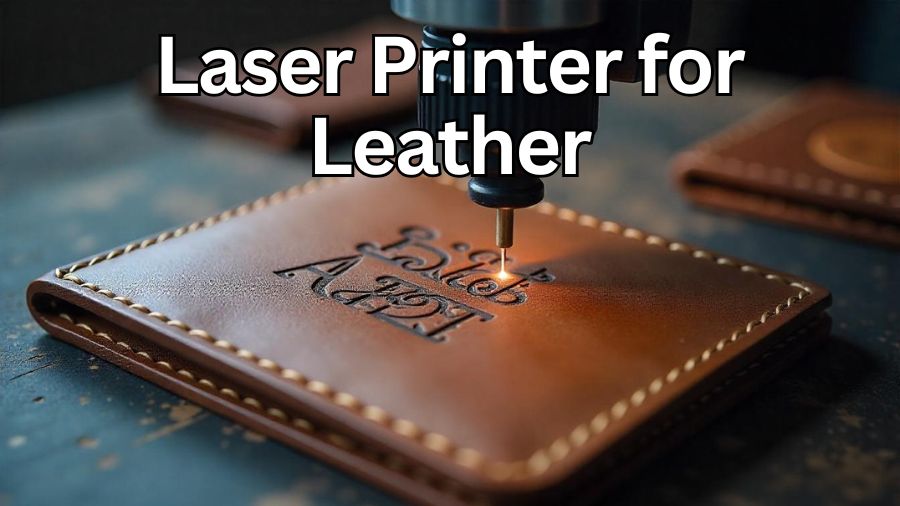

Laser printing on leather is a fantastic way to add detailed, unique designs to leather items. By using a laser printer, you can engrave names, patterns, and images onto wallets, belts, handbags, and more. This technique is popular among both hobbyists and businesses because it can personalize and decorate leather items quickly and precisely.

Unlike traditional printing, laser engraving doesn’t use ink. Instead, it uses a focused laser beam to cut or mark the leather surface. The laser works by heating the leather, removing the top layer to reveal the design underneath. This process creates clean, sharp details that can last a long time, even on frequently used items.

Laser engraving on leather can make each item look professional and unique. With so many possibilities, people are using laser printers on leather to create custom products, from everyday items to special gifts.

Types of Laser Printers Suitable for Leather

Choosing the right type of laser printer for leather is essential. Different lasers have unique strengths, and each type works better for certain leather projects. Let’s explore the main types:

CO2 Lasers

CO2 lasers are the top choice for leather engraving. They can cut, mark, and engrave leather with great precision. CO2 lasers use a strong, steady beam to create clear, detailed designs without damaging the leather. This type of laser works well with most leather types, including thicker pieces. CO2 lasers can create both deep cuts and light surface markings, depending on the settings.

Diode Lasers

Diode lasers are smaller and less powerful. They’re mostly used for lighter jobs, like surface marking or creating shallow designs on leather. Diode lasers are popular with beginners or hobbyists because they’re more affordable. However, they may struggle with thicker leather, so they work best on thin or soft leather surfaces.

Fiber Lasers

Fiber lasers are known for their speed and ability to mark metals. While they’re less common for leather, they can still be used to make sharp, lasting marks. Fiber lasers don’t go as deep as CO2 lasers, but they can add serial numbers, logos, or simple designs. Fiber lasers are ideal for small markings rather than full engravings.

Each type of laser offers unique possibilities for leather projects. CO2 lasers provide flexibility for deep and shallow designs. Diode lasers work well for simple, small projects. Fiber lasers create lasting marks for branding or labeling. The right laser choice depends on the type of design you want and the thickness of the leather.

Here’s a comparison table for the different types of laser printers suitable for leather engraving:

| Laser Type | Best For | Power Level | Depth of Engraving | Common Uses | Cost Range |

|---|---|---|---|---|---|

| CO2 Laser | Thick and thin leather | High (40+ watts) | Deep and shallow engravings | Belts, wallets, bags | Moderate to High |

| Diode Laser | Thin or soft leather | Low (less than 10 watts) | Shallow, light markings | Small DIY projects, surface designs | Low to Moderate |

| Fiber Laser | Marking metals and certain leathers | Moderate (varies) | Mostly surface marking | Branding, logos, small engravings | High |

This table outlines the key differences to help you choose the right laser type for leather engraving.

Choosing the Right Leather for Laser Printing

Vegetable-tanned leather is one of the top choices for laser engraving. This type of leather is treated with natural materials like tree bark or leaves. This makes it sturdy and durable while also being safe for engraving. Vegetable-tanned leather produces minimal smoke, which means a clearer and cleaner design. It is also less likely to discolor over time, keeping engravings sharp and easy to read.Full-Grain and Top-Grain Leather

Full-grain leather is thick and durable, offering a high-quality finish that works well for deep engravings. Top-grain leather is slightly thinner and more flexible but still provides a good surface for engraving. Both types are reliable choices for leather projects that need a professional look. However, full-grain leather requires careful settings to avoid burning due to its thickness.Leathers to Avoid

Some types of leather are not ideal for laser engraving. For instance, chrome-tanned leather often contains chemicals that can release harmful fumes when engraved. Additionally, synthetic leathers can melt or burn unevenly under the laser. While some synthetic leathers are designed to handle laser engraving, many are best avoided to prevent damage or toxic fumes.

Factors to Consider

When choosing leather, consider factors like thickness, color, and finish. Thicker leather is better for deeper engraving, while lighter-colored leather offers more contrast, making designs more visible. Leather with minimal finishing or coating engraves more easily, as the laser can interact directly with the surface.

The right leather makes a big difference in engraving quality. By picking the best type, you can achieve crisp, lasting designs with fewer issues.

Key Considerations for Successful Leather Engraving

To achieve the best results when engraving leather, it’s essential to adjust your laser settings and prepare the material properly. A few simple tweaks can make all the difference between a clear, lasting design and a blurry or burned result. Here are some key factors to keep in mind:

Power and Speed Settings

Finding the right balance between power and speed is crucial for clean engravings. If the laser power is too high, it can burn or damage the leather. If it’s too low, the engraving may not be visible. Start with a low-to-medium power setting, especially on thinner leathers. Increase the power gradually if needed. The speed setting should be higher to keep the laser moving swiftly across the surface, reducing the chance of over-burning.

Focus and Precision

Precise focus is another important step for quality engraving. A well-focused laser ensures that each line is crisp and detailed. Most lasers have an adjustable focus that can be aligned to the thickness of the leather. Double-check the focus before you start, as even a slight misalignment can make designs appear blurry.

Pre-Engraving Surface Preparation

Clean the leather surface before engraving. Dust or oil on the leather can affect the engraving quality, leading to smudges or uneven cuts. A quick wipe with a soft, damp cloth will usually do the trick. Let the leather dry completely to avoid any reaction with the laser heat.

By managing power, speed, focus, and preparation, you can create a well-defined design that looks professional. These steps help reduce mistakes, allowing for smooth, clear engravings on each project.

Popular Applications of Laser Engraving on Leather

Laser engraving on leather opens up a world of creative possibilities. This method allows for personal touches and designs that make leather goods stand out. Here are some of the most popular ways people use laser engraving on leather:

Belts

Engraving leather belts is a great way to add a personal touch. Whether it’s a name, logo, or pattern, a laser-engraved belt is unique. Deep engravings work well for these, creating a design that’s both durable and stylish.

Wallets

Wallets are another favorite for laser engraving. Many people enjoy adding initials, quotes, or small graphics to personalize these everyday items. Light engraving or etching works best here to keep the surface smooth while adding a clear design.

Bags and Purses

Engraving bags or purses adds a touch of elegance and individuality. This is common in custom leather goods, where customers can choose specific designs. Detailed engravings look great on leather bags, and the designs often reflect the owner’s style or interests.

Leather-Bound Books

Personalized leather-bound journals or books make thoughtful gifts. Adding a name, date, or meaningful message can turn a simple book into a keepsake. Light, shallow engravings are often used on book covers to keep the surface smooth.

Accessories and Keychains

Small items like leather keychains or bracelets are popular for engraving simple designs. Names, symbols, or short phrases fit well on these items. The engravings are usually shallow, making them more decorative than functional.

Laser engraving allows for endless customization on leather goods, making each item special. With a few simple designs, everyday leather items can become meaningful, one-of-a-kind pieces.

Here’s a comparison table for popular applications of laser engraving on leather:

| Application | Common Designs | Engraving Depth | Purpose | Surface Finish |

|---|---|---|---|---|

| Belts | Names, logos, patterns | Deep engravings | Personalization, style | Durable, bold designs |

| Wallets | Initials, quotes, small graphics | Light to medium engravings | Everyday personalization | Smooth, subtle |

| Bags and Purses | Custom designs, symbols | Deep or detailed engravings | Unique style, individual branding | Textured, elegant |

| Leather-Bound Books | Names, dates, messages | Light, shallow engravings | Keepsakes, gifts | Smooth, professional |

| Accessories & Keychains | Simple symbols, names | Shallow engravings | Decorative, personal | Lightweight, decorative |

This table highlights how different leather items benefit from various engraving depths, designs, and finishes, making them ideal for custom, personalized looks.

Recommended Laser Printers for Leather

Finding the right laser printer for leather can make a huge difference in quality and ease of use. Here are some of the best laser printers for leather engraving, each suited for different needs and budgets:

Glowforge Basic

Glowforge is a popular choice for leather engraving, especially for beginners and small businesses. The Glowforge Basic uses a CO2 laser, which is highly effective on leather. It is user-friendly, with easy software and simple setup. It can handle detailed engravings and even some light cutting. However, it’s best for smaller items like wallets or keychains, as its work area is more limited.

Omtech CO2 Laser Engraver

Omtech offers a variety of CO2 laser engravers, including models with larger workspaces and higher power. This makes it suitable for engraving larger leather items like bags or belts. Omtech lasers are often praised for their strong performance and reasonable price. They offer different power levels, so you can choose one based on your project size and leather thickness.

Boss Laser LS-1416

The Boss Laser LS-1416 is a CO2 laser known for its high precision and powerful engraving capabilities. It’s ideal for thicker leather projects or for detailed designs that require depth. Boss Laser machines are built to last, making them a good option for those who plan to do regular leather engraving. The LS-1416 model has a decent-sized workspace, fitting mid-sized leather items comfortably.

xTool D1 Pro

The xTool D1 Pro is a diode laser, making it a budget-friendly option for light leather engraving. Diode lasers are not as powerful as CO2 lasers, so the xTool D1 Pro works best on thin leather or smaller projects. It’s a good choice for beginners or hobbyists who want to explore leather engraving without a big investment. However, it may not handle thick leather or deep engraving.

Trotec Speedy 100

The Trotec Speedy 100 is a high-end CO2 laser engraver, known for its speed and precision. It’s designed for professional use, making it a top choice for businesses that handle large volumes of leather engraving. The Trotec Speedy 100 offers an extensive work area and high power, suitable for deep engravings on thick leather. While it’s more expensive, it delivers excellent quality and is highly durable.

Each of these laser engravers has unique features that make them suitable for different types of leather projects, from small DIY tasks to professional custom work. Consider the size, power, and cost to find the best option for your needs.

Tips for Beginners in Leather Laser Printing

Starting with leather laser printing can be exciting but requires a bit of practice. Here are some helpful tips for beginners to make sure each project comes out great:

1. Test on Scrap Leather

Before engraving on your final item, try a test run on scrap leather. This allows you to see how the design will look and helps you adjust the settings. Scrap pieces let you practice without worrying about mistakes on the main project.

2. Start with Lower Power and Speed

Begin with low power and high speed to avoid burning the leather. Once you see how the leather reacts, you can slowly increase the power if needed. It’s easier to make a design deeper than to fix burned or overdone areas.

3. Adjust for Contrast

Contrast is important to make the design stand out on the leather. Light-colored leather gives the best results for engraving because it creates a clear, visible design. Dark leather can be engraved, but the results may be less visible.

4. Ventilation is Key

Laser engraving leather produces smoke and fumes. Make sure you work in a well-ventilated area or use a fume extractor. This keeps the workspace clear and prevents smoke from clouding the laser, which can impact the engraving quality.

5. Clean Up After Engraving

After engraving, gently wipe the leather to remove any residue. This brings out the design and leaves the leather clean. Use a soft, dry cloth to prevent scratches, and avoid any harsh chemicals that could damage the leather.

These simple tips can make a big difference in the quality of your leather engraving projects. With some practice and patience, you’ll be able to create professional-looking designs on leather every time.

Conclusion: Laser Printing on Leather for Everyone

Laser printing on leather is an exciting and creative way to personalize leather goods. Whether you are designing belts, wallets, or bags, a laser printer can help you bring your ideas to life with precision and detail. By choosing the right laser printer, understanding the types of leather that work best, and making small adjustments to settings, you can create stunning, professional results.

With the right tools and a bit of practice, anyone can start making custom leather items. It doesn’t matter if you’re a hobbyist or a small business owner—laser engraving offers endless possibilities. Keep experimenting, and you’ll soon be able to design high-quality leather items that stand out. The key is patience, practice, and using the best materials and equipment for the job.

Laser printing on leather not only enhances creativity but also adds value to everyday products. So, whether you’re making gifts, selling custom pieces, or just enjoying the process, laser engraving on leather is a fantastic skill to learn.

Frequently Asked Questions (FAQ)

1. Can I use any leather for laser engraving?

Not all leathers are suitable for laser engraving. Vegetable-tanned and full-grain leathers are the best choices. Avoid chrome-tanned and synthetic leathers as they may release harmful fumes or not engrave well.

2. How deep can I engrave leather?

The depth of engraving depends on the type of laser and settings. CO2 lasers can engrave deeply, while diode lasers are better for lighter, surface designs. Thicker leather may require more power to engrave deeply.

3. Can laser engraving be done on colored leather?

Yes, laser engraving works on colored leather. However, light-colored leather gives the best contrast, making the design more visible. Dark leather may not show the design as clearly, especially for subtle engravings.

4. Do I need special software for laser engraving leather?

Yes, most laser engravers require design software to create and adjust the patterns. Programs like Adobe Illustrator or CorelDRAW are popular. Many laser machines come with their own software that is easy to use for beginners.

5. What safety precautions should I take when laser engraving leather?

Make sure to work in a well-ventilated area. Leather can produce smoke and fumes when engraved. Always use a fume extractor to protect your health. Also, wear safety glasses to protect your eyes from the laser beam.

6. Can I use a laser printer to cut leather?

Some laser engravers are also capable of cutting leather. CO2 lasers are often used for both engraving and cutting. However, the thickness of the leather will affect the cutting ability. Thinner leather is easier to cut than thicker leather.

7. How do I maintain my laser engraver?

To maintain your laser engraver, clean the lens and mirrors regularly. Check for dust buildup, especially in the exhaust system. Keeping the machine clean will help it run efficiently and extend its lifespan.

8. Can I create custom leather gifts with a laser printer?

Yes, laser engraving is perfect for creating custom gifts. You can engrave names, dates, or personal messages on leather items like wallets, belts, and keychains. This makes for thoughtful, unique presents.